Better Seafood through Chemistry

Not long after nutrition scientists confirmed that the typical American diet was a heart attack's best friend, seafood began to fill a larger share of what we once thought of as the meat section in supermarkets. Prices for popular seafood, such as salmon and crab, began to climb to realms once reserved for tenderloin and t-bone. The stage was set for surimi.

Surimi is what amounts to the starter kit for the relatively inexpensive so-called seafood analogs--artificial crab, shrimp, and scallops, for example. But it's real seafood: it is walleye pollock, a codfish cousin and the most abundant fish taken from the Bering Sea.

All codfishes need to be eaten fairly quickly after they are caught, and they don't keep long even if they are frozen. Pollock pushes this tendency to an extreme; its keeping qualities are poor, even compared to Pacific cod, for example.

The key to pollock's relatively swift loss of quality is a set of chemicals, an enzyme-substrate system that can generate formaldehyde even in frozen fish. This chemical degradation makes pollock fillets or even minced fish turn rubbery during storage. The surimi process avoids the problems by swiftly removing the troublesome chemicals.

The fish are beheaded, gutted, and washed, then put through a machine that separates flesh from skin and bone. The meat is put through a drum with small-diameter holes, producing minced pollock meat. The minced fishmeat is washed repeatedly in cold water until all the enzymes, blood, fat, and anything else that might cause odors or other problems has been removed. What remains is nearly pure fish protein.

To this is added cryoprotectants such as sugar and salt, substances that ensure the flesh will not lose its gel-forming properties or break down during a year's frozen storage. At this stage, the processed pollock can be called by its Japanese name, surimi.

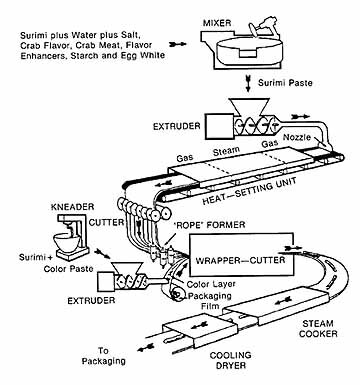

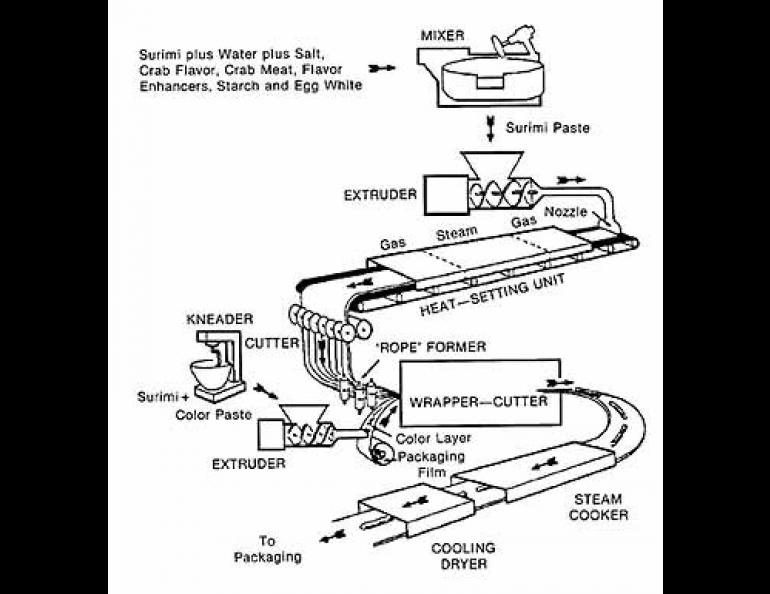

Surimi is not the product available in supermarkets; several transformations remain. The surimi is next mixed with spices, flavoring, starch (to improve its texture), and egg white (which makes it stronger for forming, glossier, and whiter). The pollock paste now has become kamaboko, a generic term for the raw material of fishstuff, so to speak, like dough for breadstuff.

Like dough, the kamaboko needs to be shaped and cooked before it is packaged and sold. It can be extruded to produce different textures and formed into various shapes, depending on the kind of seafood the final product is to imitate; each shape or texture requires a different kind of machine.

For example, imitation king crab legs need to have a stringy texture. To obtain the right effect, the kamaboko is extruded through a wide but flat nozzle into a sheet of paste, then briefly heated. After heating, the sheet is stronger and more elastic. It is then cut, but not all the way through, into a series of strips like barely attached fine noodles. These strips are then folded into a structure that resembles a rope containing a series of longitudinal fibers. The rope is wrapped in a very thin layer of reddish-colored surimi, to mimic the color shown by real crabmeat next to the shell. Cooked and cut to the proper length, the end result is acceptable in both appearance and flavor as imitation crab legs. The same material, first cut in larger strips and then with the rope-like phase cut at angles instead of straight, looks very like crabmeat chunks or flakes.

No addict of real king crab could mistake surimi for the genuine article, but surimi-based products are popular. In 1984, the U.S. imported 29 million pounds of it. About 95 percent of that started out as walleye pollock hauled from the Bering Sea and Gulf of Alaska. Alaska is now moving toward surimi production, as University of Alaska researchers at Kodiak work with manufacturers there and elsewhere around the state to provide a better product. For Alaskans, the boom in surimi is a case of local fish making good.